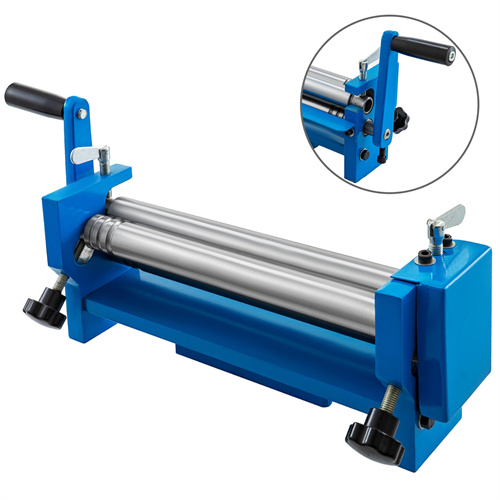

F4 two-in-one fishtail forming machine is developed from the F3, it have another function which we called “spearhead”. So it

F4 two-in-one fishtail forming machine is developed from the F3, it have another function which we called

“spearhead”. So it combine “fishtail” and “spearhead” in one machine, It can solve two problem. So low

down the buying cost very much.

Technological Depiction:

F4 two-in-one fishtail rolling machine | ||

Max Working Ability | Square Steel | ≤16mm×16mm |

Round Steel | ≤Φ16mm | |

Flat Iron | ≤10mm×60mm | |

Motor Performance | Power:2.2W(Class 6) Voltage: 380V 50HZ | |

Main Features | 1. No need to beat and chamfer the steel, it can forging the steel end to fishtail after heat the steel. The end become winder and thinner, the thickness is more than 2 mm. 2. It use cyclonical speed reducer, large torque. It adopts special way for the torque transmission between the gear box and working case. Ensuring smooth and reliable mechanical operation. 3. There have location device behind the machine, we can set the material effect entrance length according the requires. So we can get the best effect product. 4. When we process 10mm or bigger steel, we can use the wide design of the mold and then get the more beautiful fishtail pattern. 5. This machine have a wide process range, large working ability, high efficiency, we can produce 300 pieces of 8*40mm fishtail. 6. The mold material is good qualitym long life time, and each roller can forging at least 100,000pieces. | |

Packing Dimension | 1165mm×560mm×1100mm | |

N.W. (kg) | 300 | |

G.W. (kg) | 350 | |